Principle of Wet Gas Flow Meter

Category: Drum type wet gas meter

Time:2024-05-05

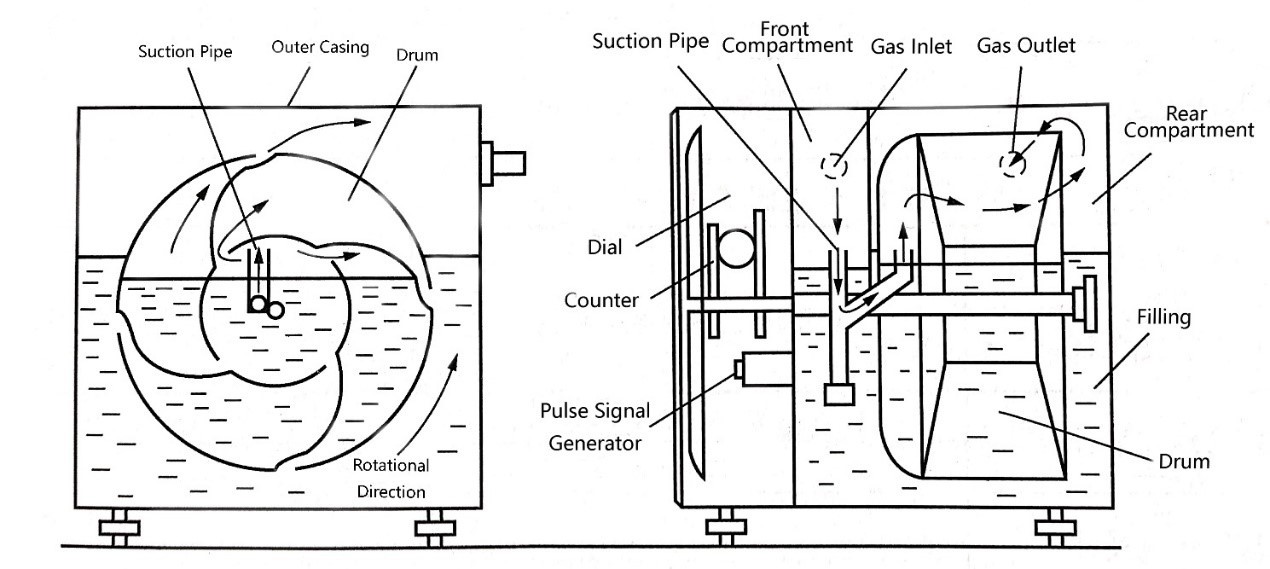

The wet gas flow meter is composed of an outer shell, a metering drum, a counting mechanism and a dial. The wet gas flowmeter uses low-viscosity oil or water as the sealing liquid, and 3/5 of the diameter of the metering drum is immersed in the liquid and rotates clockwise with the inflow and outflow of the gas. The measuring drum is cylindrical and divided by 4 groups of blades into a zigzagging measuring cavity with no ventilation and equal theoretical volume. The rotating shaft is placed horizontally in the center of the front and back shell end cover. The rear end cover of the metering drum of the wet gas flowmeter and the blade form an intake chamber. The opening is the intake port of the metering chamber, and the opening of the front end blade is the exhaust port of the metering chamber. The wet gas flowmeter housing has a group of instrument level benchmarks on the top and a level height benchmark on the side. When the wet gas flowmeter works, it uses the gas pressure difference force between the inlet and outlet to push the metering drum to rotate. The pointer and the driving gear, which are clamped on the spindle of the measuring drum, rotate synchronously with the drum, and are driven by the driven gear with a certain speed ratio to convert the rotation times of the measuring drum into volume, which is accumulated by the mechanical counter. Electronic high-precision wet gas flowmeter is also equipped with thermometer, pressure gauge, digital signal interface.

In the process of gas metering, the drum shaft rotates synchronously with the drum, and drives the pointer installed on the front panel and the rotary encoder or mechanical counter on the shaft through the magnetic transmission mechanism, and displays the volume value of the flow out synchronously on the dial and the integrator.

Keywords:

EN

EN RU

RU SP

SP